No more raising and lowering the helmet for tack welds. No more sloppy starts because the torch moved. When the sensors on the helmet sense an arc start, the lens automatically darkens, in a fraction of a second (typically 1/12,000 to 1/20,000 of a second for industrial-grade helmets), to shade #8 to #13.īecause the helmet stays in position before, during, and after the weld, an auto-darkening welding helmet allows you to set up your welding joint with the hood in position. When inactive, an auto-darkening lens usually has a #3 or #4 shade, which is relatively easy to see through.

If the helmet fails to lock onto position or if the timing is out, it can lead to inadvertent arc flashes if the arc strikes before the helmet is in place.Īn auto-darkening lens addresses the above issues. Welders need to repeatedly flip the helmet up and down which can cause neck fatigue, and possibly repetitive stress injuries. This can cause poor weld starts, which may lead to weld defects or the need for excessive grinding.īecause of the need to repeatedly lift and lower the helmet, tack welding, or numerous short welds, can be difficult.

It can be difficult for novice welders to position the electrode while the helmet snaps into place. Passive lens helmets provide an economical choice however, they have some cons: With a quick nod or snap of the neck, the operator flips the helmet into position immediately before striking an arc. This helmet is worn in the up position while the electrode, gun or torch is positioned.

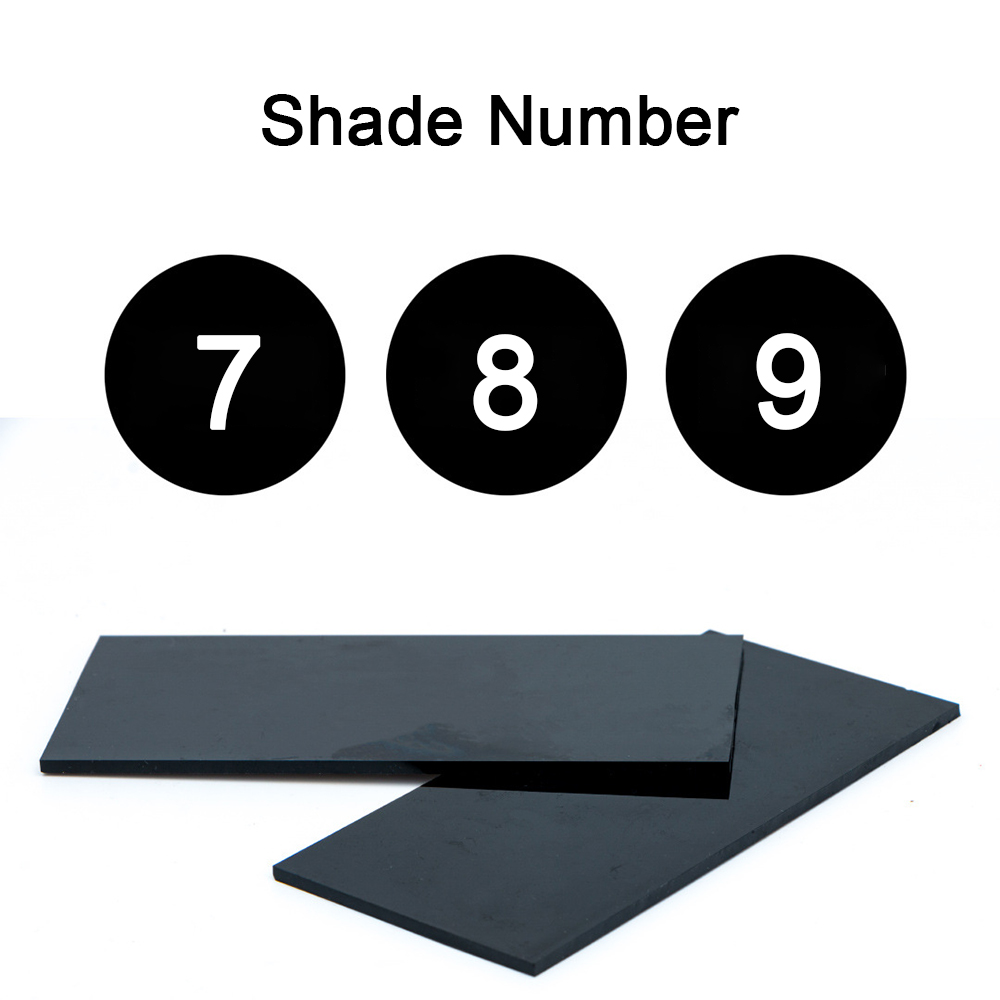

All auto-darkening welding helmets that meet the Australian standard AS/NZS 1338.1 provide 100% protection against harmful infrared and UV rays and may range from a #8 shade for low-amp applications up to a #13 shade for high-amp applications.Ī passive lens helmet uses UV- and IR-coated dark-tinted glass with a fixed shade value, usually #10. Welding lens shade numbers refer to the lens' ability to filter light. This ensures that the helmet and lens has passed independent testing and can survive high impact from flying objects, provide 100% ultraviolet and infrared filtering regardless of shade setting, and meet advertised switching speeds and darkness shades in temperatures as low as -5 degrees and high as 55 degrees. The helmet you choose should meet Australian Standards AS/NZS 1338.1 (Auto-Darkening) and AS/NZS 1337.1 B (High Impact). Take the time and find the right helmet for your needs, it can increase your productivity, weld quality and comfort. There are a large range of welding helmets available in the market, such as a passive or auto-darkening lens, fixed or variable shade, two, three or four sensors and viewing size.

0 kommentar(er)

0 kommentar(er)